MV™ SERIES

UPTIME

Our trucks are built to carry the weight of your job, your reputation, and your commitment to deliver.

SAFETY

Our commitment to safety can be seen in thoughtful design, engineering, and features of the new MV Series.

INTEGRATION

Ease of doing business just got easier with more application upfit options.

Cab Options

All MV Series models are now available in the following cab options:

- Extended Cab

- 4-door Travel Crew Cab

- Day Cab

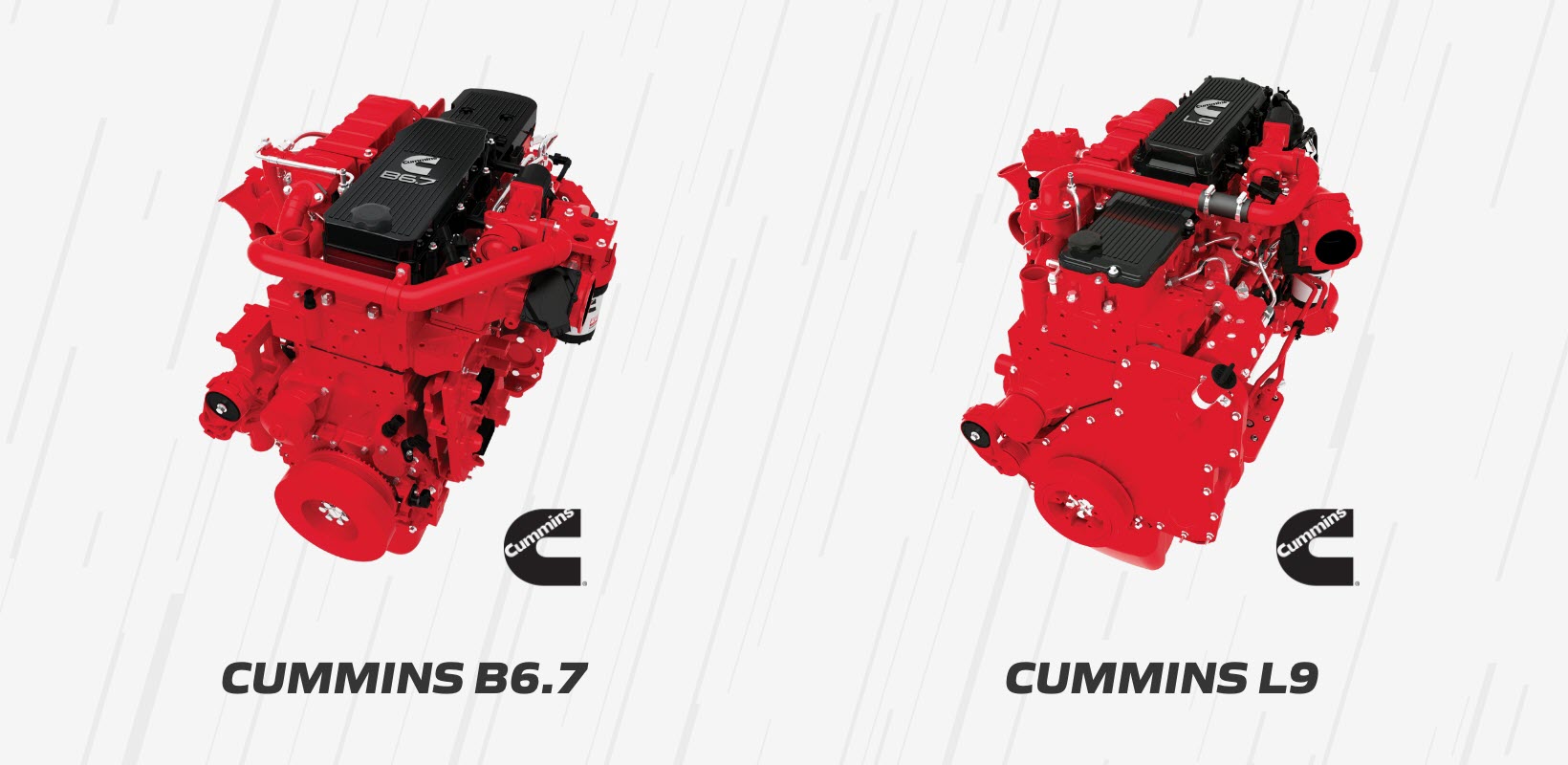

Engines

All MV Series models are available with the following engines

Cummins B6.7

- 200-360 hp

- 700-800 lb.-ft

Cummins L9

- 260-360 hp

- 860-1,150 lb.-ft

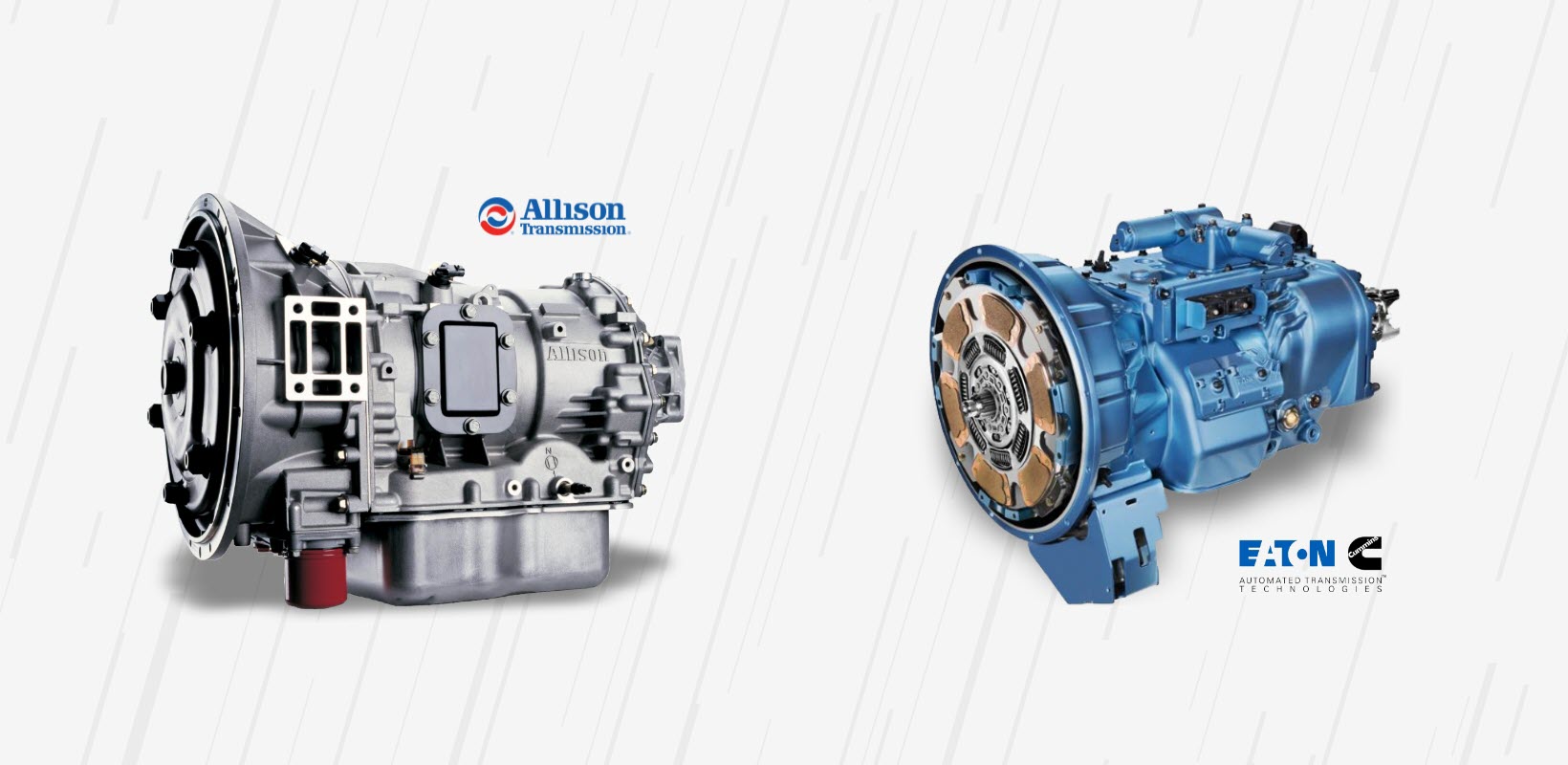

Transmissions

All MV Series models are available with the following transmissions:

Automatic

Allison: 1000, 2000, 3000 Series (HS, EVS, RDS, MH)Manual

Eaton Fuller: 6-speedEaton Fuller: 10-speed

Interior Trim Options

All MV Series models are available in the following trims:

- Classic Trim: Classic interior trim includes neutral color inserts on the doors and instrument panel, black interior door handles

- Diamond Trim: Diamond trim upgrades include dark neutral accents and bright door handles, providing a more upscale interior

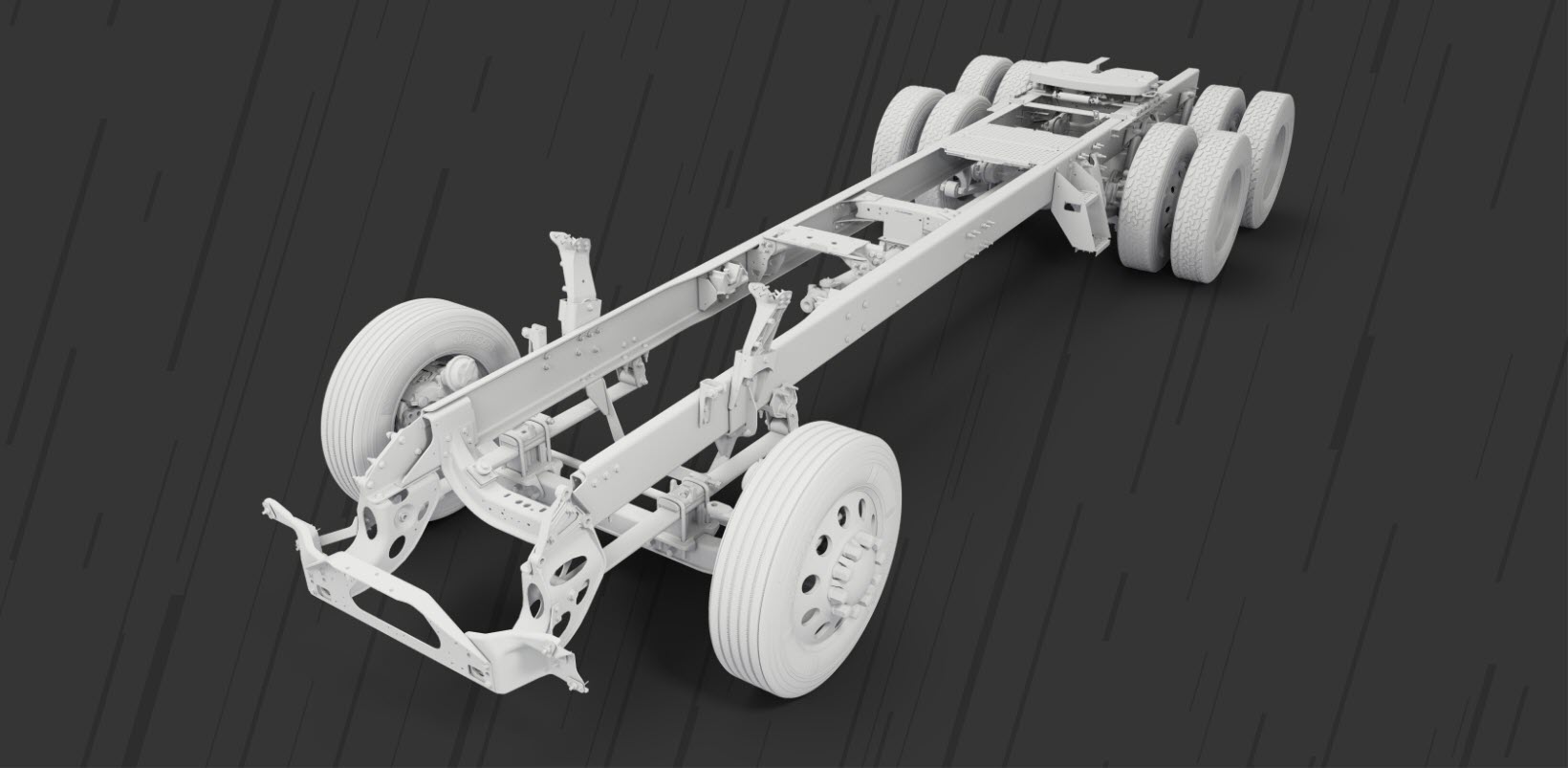

Chassis Configurations

All MV Series models are available in the following configurations:

Low Cab 4x2

Engine: Cummins B6.7GVWR:

GVWR: 17,900 - 37,000 lbs.

Wheelbase: 128-311"

Low Cab 4x2 Low Profile

Engine: Cummins B6.7

GVWR: 17,900 - 29,000 lbs.

Wheelbase: 140-254"

Mid Cab 4x2

Engine: Cummins B6.7

GVWR: 17,900 - 37,000 lbs.

Wheelbase: 128-311"

Engine: Cummins L9

GVWR: 21,000 - 44,700 lbs.

Wheelbase: 128-311"

Mid Cab 4x2 Low Profile

Engine: Cummins B6.7

GVWR: 17,900 - 37,000 lbs.

Wheelbase: 128-311"

Engine: Cummins L9

GVWR: 21,000 - 29,000 lbs.

Wheelbase: 128-311"

Mid Cab 6x4

Engine: Cummins L9

GVWR: 44,000 - 54,700 lbs.

Wheelbase: 152-311"

Low Cab Tractor 4x2

Engine: Cummins B6.7

GVWR Max: 52,000 lbs.

Wheelbase: 138-254"

Mid Cab Tractor 4x2

Engine: Cummins L9

GVWR Max: 80,000 lbs.

Wheelbase: 138-254"

Engine: Cummins L9

GVWR Max: 52,000 lbs.

Wheelbase: 138-254"

Mid Cab Tractor 6x4

Engine: Cummins L9

GVWR: 80,000 lbs.

Wheelbase: 156-197"

Available Warranties

All MV Series models are available with the following warranties (unless noted):

- Standard Warranty

Base Vehicle Coverage: 2 years, unlimited mileage*

Drivetrain Coverage: 3 years, unlimited mileage

Chassis Coverage: Frame side rails: 7 years, unlimited mileage

Cab/Cowl Structure: 5 years, unlimited mileage

Cab/Cowl Perforation Corrosion: 5 years, unlimited mileage -

Extended Warranty Options:

- A variety of extended service contracts are available in addition to the base warranty, which includes: engine components, full chassis, chassis components (HVAC, electrical, starter/alternator)

- Supplier extended service contracts are also available: Cummins® engine components, Eaton transmissions, and Hendrickson suspensions

* See warranty page for details.

Warranty DetailsA LOOK INSIDE THE TRUCK

MV™ SERIES

UTILITY APPLICATION

MV™ SERIES

SNOWPLOW APPLICATION

MV™ SERIES

DRY VAN APPLICATION

GETTING THE JOB DONE.

A VISION FOR SAFETY

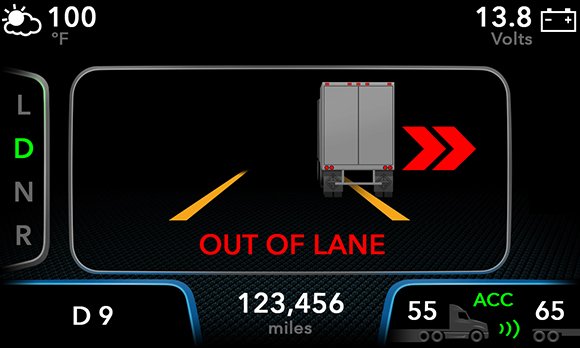

BENDIX® WINGMAN® ADVANCED™

The optional Bendix® Wingman® Advanced™ and Bendix® Wingman® Fusion™ collision mitigation systems can greatly enhance operator safety. By integrating adaptive cruise control, lane departure warning, over-speed alert and stationary vehicle braking, these cutting-edge systems can help the driver potentially avoid a collision or help reduce its severity.

BENDIX® WINGMAN® FUSION® adds:

- Radar and a video camera scan the forward path of the truck

- Stationary vehicle braking can automatically alert the driver and apply brakes

- Multi-lane autonomous emergency braking (AEB)

- Highway departure warning and braking (HDW/HDB)

- Lane departure warning

- Overspeed alert & action can read speed limit signs and notify the driver and fleet of overspeed travel

- Available Bendix™ SafetyDirect® can capture data and transmit driver performance and event-based information – including video. – to the SafetyDirect web portal

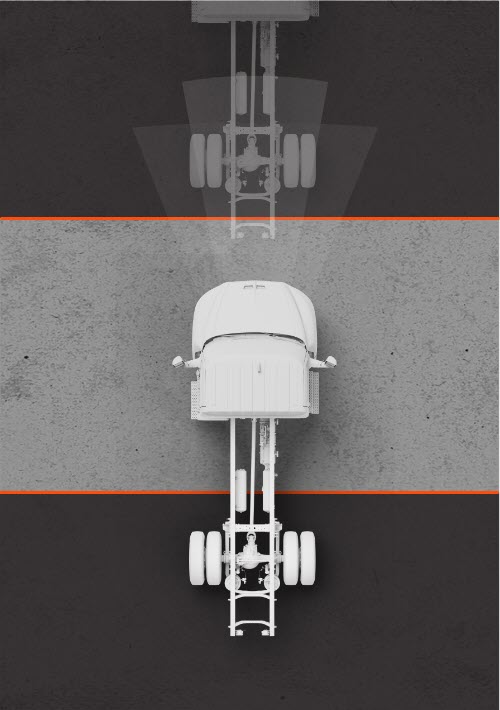

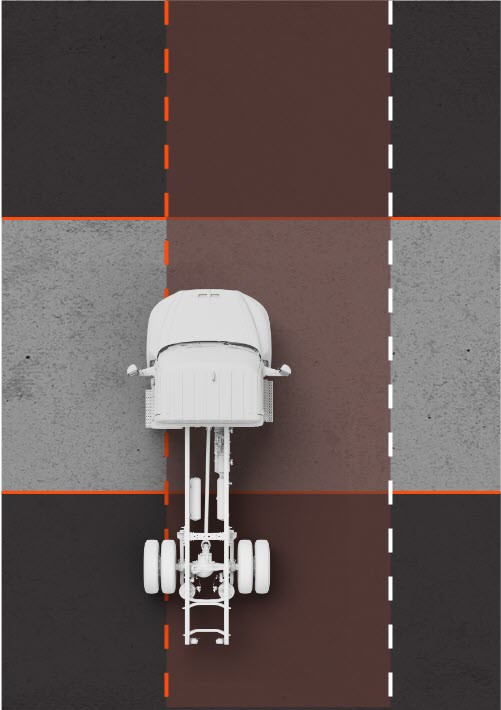

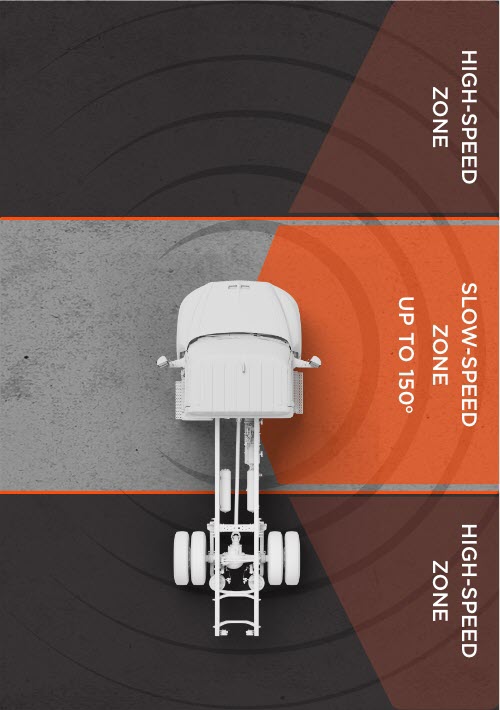

BENDIX® BLINDSPOTTER®

When connected to the vehicle’s Control Area Network (CAN), the optional Bendix BlindSpotter provides a 150° range of coverage capable of detecting objects up to 20 feet in front of and 20 feet behind the BlindSpotter radar. The coverage zone extends up to 10 feet to the right of the vehicle. BlindSpotter minimizes false alerts by operating in two modes: highway speeds and lower speeds.

STEEL SANCTUARY

For Strength, Safety and Comfort

The MV Series cab wraps your crew in a high-strength, low-alloy (HSLA) reinforced, cold-rolled steel construction that combines the corrosion resistance of aluminum with the world-class fit, finish, and strength of steel. The result is a larger, quieter, more protective interior with air- and water-tight seals.

INTERCOAT® CHEMGUARD

Think of it as a self-healing layer of skin on our galvanized steel. This inter-reactive, chrome-zinc phosphate coating is used on floor and toe kick panels to help extend integrity. The self-rejuvenating properties allow surface cuts, scratches, and perforations to maintain corrosion protection.

OPTIONAL SPRAY-ON FLOOR PROTECTION

This available polyurethane and polyurea formulation creates a protective tray on the cab floor that contains spills, as well as any of nature’s elements that make their way inside. Durable and long-lasting, the optional spray-on liner is an OEM-grade protective coating designed to guard against abrasion, corrosion, and impact and can be found on over 4 million pickup bedliners.

Top-Down Strength

All MV™ Series configurations (regular, crew and extended cab) pass the rigorous SAE J2422 roof strength test and Huck Bolt chassis fasteners provide extra clamping force without the need to re-torque, so they won’t come loose even under high stress loads.

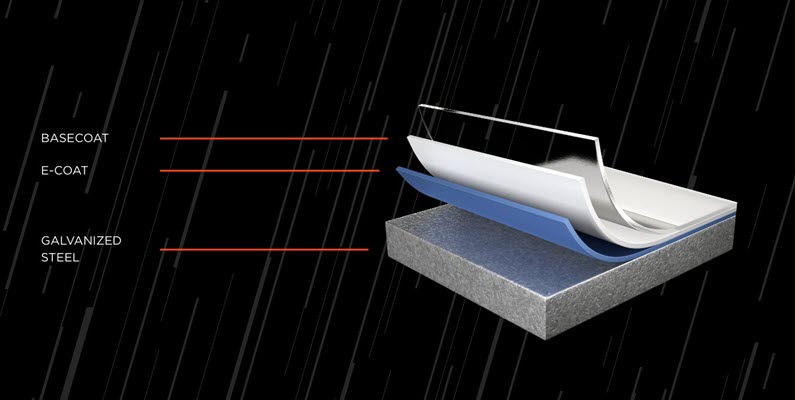

Anti-Corrosion That’s Anti-Compromise

At International Truck, longevity is the head of the hammer. Which is why every welded MV Series cab assembly is dipped into an electrostatically-applied primer as part of a rigorous paint, sealing, and coating process that provides superior corrosion and fade resistance – all backed by a 5-year perforation corrosion warranty.

CORROSION PROTECTION PROCESS

- Stamped steel with 60G/60G dual sided galvanized coating - standard on dash and toe and floor panels

- Custom-engineered caustic and surfactant formula cleans and preps the steel

- Proprietary tri-metal (nickel, zinc, manganese) phosphate blend provides robust corrosion protection and the first level of pain adhesion

- Epoxy-based electrodeposition primer, or e-coat, is applied. This covers and seals the entire exposed metal surface of the cab

- Acrylic basecoat

- Urethane clear coat

DIAMOND LOGIC® ELECTRICAL SYSTEM

The International® Truck Diamond Logic® electrical system is considered the most advanced in the industry—and for good reason. Diamond Logic streamlines chassis and body equipment integration and allows customers to program automated tasks. This means more consistent performance and increased equipment protection and crew safety.

SIMPLIFY AND REDUCE COST OF BODY INSTALLATIONS

- • Plug and play components

- • No hardwiring into fuse panels and relay boxes

- • No dash disassembly for switch installations

- • Integrated lights/buzzers

- • Supplies pigtails which enable power & signal to be pulled direct from the harness

- • Compatible with factory-installed lift axles

CLEANER FIT AND FINISH OF INSTALLATIONS

- • No need to cut into dash when using switch packs

- • Flexible switch locations and switch type

- • Integrated backlighting and indicator lights

- • Can redefine switches without moving them

EQUIPMENT PROTECTION

- • PTO interlocks

- • Equipment interlocks

- • Load shedding

- • Theft deterrent

FEATURES

Exterior/Mechanical

-

+

-

+

-

+

-

+

Interior

-

+

-

+

-

+

MV Corrosion Mitigation Spec Sheet

MV Corrosion Mitigation Spec Sheet

MV™ Boom Spec Sheet

MV™ Boom Spec Sheet

MV™ Bucket Spec Sheet

MV™ Bucket Spec Sheet

MV™ Snowplow Spec Sheet

MV™ Snowplow Spec Sheet

MV™ Utility Spec Sheet

MV™ Utility Spec Sheet

MV™ Van Spec Sheet

MV™ Van Spec Sheet

MV™ Recovery Spec Sheet

MV™ Recovery Spec Sheet

MV™ Brochure

MV™ Brochure