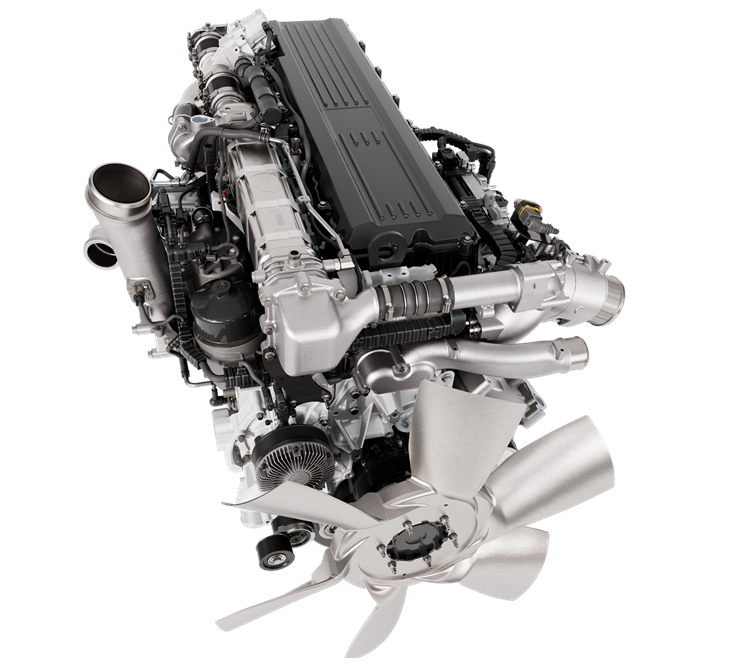

Lightweight Knockout

THE A26 IS PACKED WITH EFFICIENT MUSCLE.

The A26 produces up to 515 HP and 1850 lb.-ft. of torque, but its big-bore performance only begins to tell the full story of this engine. The modern simplicity of the A26 design does more than shed weight — every component has been carefully engineered to deliver uncompromising uptime and fuel efficiency, reduced weight and quieter operation.A Best-In-Class Standard Warranty Coverage

-

Optional Engine Warranties

Up to 7 years and 700,000 miles

-

Standard Engine Warranty

2 year unlimited mile warranty

Maintenance Intervals

-

Replace Engine Oil and Oil Filter

Up to 70,000 miles with oil sampling and International Truck approval

6.5 or greater mpg: 50,000 miles (80,000 km)

5.5 to 6.5 mpg: 30,000 miles (48,000 km)

Less than 5.5 mpg: 20,000 miles (32,000 km) -

Replace Fuel Filter

At every oil change or 1,300 hours

-

clean dpf

6.5 or greater mpg: 600,000 miles / 11,000 hours

5.5 to 6.5 mpg: 500,000 miles / 9,000 hours

Less than 5.5 mpg: 350,000 miles / 9,000 hours -

Replace DEF Filter

300,000 miles (483,000 km)

-

Add Extended Life Coolant Extender

300,000 miles (483,000 km) / 3 years / 6,000 hours

-

Replace Coolant

600,000 miles (966,000 km) / 6 years / 12,000 hours

-

Adjust Valve Lash

At 120,000 miles (193,000 km), at 300,000 miles (483,000 km), then every 400,000 miles (643,000 km)

EVERY COMPONENT IS ENGINEERED TO MAXIMIZE UPTIME

- Strong piston pins, connecting rods and bushings optimize load distribution for enhanced durability.

- The Variable Geometry Turbocharger (VGT) features a titanium compressor wheel that delivers superior fatigue life over aluminum designs, with a simplified single stage design to reduce complexity and enhance reliability.

- The piston cooling jets increase oil pressure to improve lubrication and engine durability. Exposing less oil to hot pistons also reduces oil oxidation to improve oil drain intervals.

- Oil change service interval has been increased to 70,000 miles*.

- Aluminum castings, stainless steel tubes, composite valve covers, and optional stainless steel oil pans provide long lasting corrosion protection.

- All high temperature fasteners include a permanent coating to prevent seizing, including fasteners for the exhaust manifolds, heat shields, and turbocharger.

* with oil sampling and International approval

THE A26 IS PACKED WITH NOISE-REDUCING FEATURES

- The uniquely sculpted crankcase significantly dampens vibration.

- The High Pressure Common Rail fuel system delivers multiple injection events for smooth, quiet operation.

- The oil pan and crankcase are isolated through a specially designed rubber gasket that absorbs vibration before it can get amplified through the oil pan.

- Sophisticated calibration and programming are specifically designed to reduce engine noise.

- The 6-blade fan features fewer blades for quieter operation.**

** 6 blade fan is for LT and RH Series applications only

AT 2,314 LBS., THE A26 IS THE LIGHTEST ENGINE IN ITS CLASS

- The A26 weighs 600-700 lbs. less than 15L big-bore engines.

- The Compacted Graphite Iron (CGI) crankcase has greater strength and fatigue resistance than traditional gray iron for thinner walls, reduced weight and maximized payload.

- Valve covers are built of a durable, lightweight composite instead of aluminum.

- The shot peened aluminum flywheel housing delivers high strength with impressive weight savings over traditional iron flywheel housings.

- The simple, single stage design of the turbocharger eliminates several major components, reducing weight and complexity.

ENGINEERED TO DELIVER UP TO 4%* GREATER FUEL ECONOMY

- Maximized fuel injection pressure from the 2500 bar (36,300 psi) High Pressure Common Rail (HPCR) fuel system reduces both fuel consumption and emissions.

- The efficient design of the cylinder head coolant passages help reduce parasitic loss to the water pump.

- A simplified air management system combined with the Variable Geometry Turbocharger delivers optimal fuel economy and performance.

- An oil cooler thermostat bypass allows oil to bypass the oil cooler in colder weather to improve fuel economy.

*Over previous A26 Engine

THE ONLY OPINION THAT MATTERS: YOURS

The International® A26 has shown it’s more than up to the task since its introduction in 2016. At 2,314 lbs., it’s the lightest engine you can get over 12-liters which allows for an increased payload capacity and better fuel economy. It’s also the quietest engine in its class resulting in higher driver satisfaction and driver retention.

Ease of Service Leads to Uptime

OVER THE AIR (OTA) PROGRAMMING

Remote updates and parameter settings without bringing a truck in for service

UPPER VALVE COVER

Only the upper valve cover is removed to adjust valve lash

WIRE HARNESSES

Foam encapsulated for abrasion resistance

Molded in brackets are mounted with bolts for consistent installation

CARTRIDGE STYLE FUEL AND OIL FILTERS

HAND PRIMER FUEL PUMP

Easy access

2.5 times larger for easy use