Monarch Cement - HX Series

As both a cement manufacturer and owner of multiple ready-mix concrete and block masonry companies, The Monarch Cement Company and its subsidiaries produce and deliver millions of tons of the most durable building materials on earth to customers throughout the Midwest. To keep their products moving, Monarch needs trucks that are durable, reliable and provide the utmost safety for their drivers. With a history that spans more than a century and has involved every facet of the concrete industry, the publicly traded Humboldt, Kansas based company has seen it all.

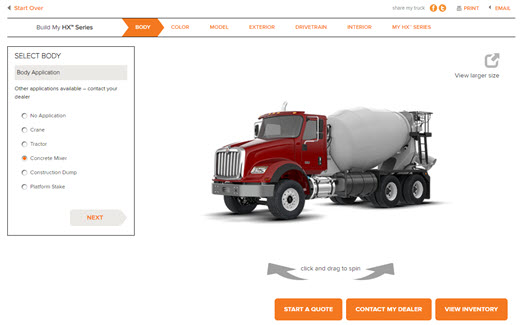

Over the years, they have run trucks from every major OEM. Value-driven and relationship-focused, Monarch pores over its own meticulously collected data prior to every purchase. These days, the numbers point them squarely to International and its versatile lineup of severe duty and over-the-road vehicles, including the International® HX® concrete mixer truck and the International® RH® bulk haul tractor – both featuring the International® A26 engine.

One of the few cement makers still based in the U.S., Monarch’s integrated model is a wonder of efficiency. The carefully choreographed process begins with mining limestone at its quarry. The limestone is mixed with clay and sandstone, is crushed, and then dried in a large roller mill. This material is then transferred to a kiln and heated to 2700 degrees Fahrenheit. At that point, the molten material undergoes a chemical transformation into a product called clinker.

This clinker is then pulverized in a ball mill to create the super-fine product, powdered cement, that is the foundation of Monarch’s success. This cement is then transported to the storage silos, where it is loaded into pneumatic trailers on bulk trucks for delivery to its customers, including its own network of ready-mix plants.

Across its home base in Kansas and 13 subsidiaries, Monarch operates a fleet featuring more than 60 tractor-trailers and 300 mixer trucks that ship its building products throughout five states. The vehicle configurations differ, but all the trucks are expected to perform in the demanding environments where they operate.

STEADY AS SHE GOES

The sturdy International HX mixers average roughly 160 hours of operation per month. During the summer months, they’ll start getting loaded at one of the ready-mix plants bright and early and make several roundtrips from area job sites before the day is done.For veteran driver Rebecca Rowan, the ride of her International HX is night and day versus competitive trucks she’s driven. “We’re in these trucks anywhere from eight to 14 hours a day,” she says.

The quietness and driver-friendly configuration of the cab is also a difference maker, helping Rowan and her fellow drivers safely navigate the controlled chaos of a typical job site to get to the precise spot of their scheduled concrete pour.

“Every little creature comfort you can get to help make the operation of the truck easier, it’s a big deal for the driver,” says Justin Tucker, Group Ready Mix Manager.

The first International HX trucks arrived at Monarch’s Missouri division in 2017: two demos provided by a persistent dealer salesperson from Summit International in Joplin. The deal allowed for Monarch to return the mixers if they did not perform as advertised. Years later, those same two trucks are still going strong in Monarch’s fleet.

POWER PLAYER

Summit doubled down a few years later, offering a similar proposition to encourage Monarch to experience the International RH tractors with A26 engines. Much like with the HX mixers, Summit and Navistar delivered a spec that matched Monarch’s matrix of needs, and included a six-year, 600,000-mile warranty.That means their own shops can focus on preventative maintenance and keeping trucks on the road. It’s also led to bottom-line savings. “By using this strategy of relationship buying and best value, we’ve made a sizeable dent in our operating costs as far as repair and maintenance,” says Webber.

Driver David “Fuzzy” Stafford got behind the wheel of the first International RH in 2019 – and never left.

The A26 has plenty of power to pull a bulk trailer of cement powder 650 miles every day, five days a week, says Stafford. “Everywhere we go, we run 80,000 pounds. There’s a lot of hills and stop-and-start driving, and it pulls great even when I’m fully loaded.”

The drivers at Monarch’s subsidiary, Beaver Lake Concrete, are paid by the load and rely on their trucks to keep running. Breakdowns are not only inconvenient; they are a drag on Monarch’s stellar reputation.

“Sitting on the side of the road won’t do you any good,” says Stafford. “We need trucks that can haul, and these trucks are very dependable. I’ve never even had a dead battery.”

The fact that the International RHs are lightweight and get about a half-gallon better fuel economy than other trucks in the fleet go a long way toward fulfilling the value proposition that Monarch prides itself on.

“We use a spreadsheet that’s almost algorithmic, and it takes a whole bunch of different factors into account to establish value,” says Webber. “Weight and payload over the life of the truck are very important. If we can haul a little bigger payload, that can swing the difference when you’re looking at the profitability you receive from that truck.”

PRIDE IN PERFORMANCE

On both the cement and the ready-mix sides of Monarch’s business, recruiting quality drivers is a constant challenge – much like it is throughout the trucking industry. “We are always looking for good drivers,” says Webber. “But we don’t just hire everyone that comes in.”From their commanding presence to their consistent reliability, the International trucks in Monarch’s fleet convey precisely the image that this widely respected company wants to communicate to everyone it does business with: from its customers who rely on their materials to build everything from highways to schools, to the employees who are its driving force.

Now more than ever, you are what you drive. Companies that provide their people with quality equipment are rewarded each workday, every single haul.

“I like the way the truck looks,” says Rowan, of her International HX, which she washes down herself at the end of every shift. “I feel proud to drive it. If you work for a company willing to buy trucks that make your job easier, you’re going to give it your all every day. And that’s exactly what I do”.